- Home

- Chemicals & Materials

-

Industrial 3D Printing Market

Industrial 3D Printing Market by Offering (Printers, Materials, Software, Services), by Application (Prototyping, Manufacturing, High Voltage), by End-User (Automotive, Electrical & Electronics, Healthcare, Aerospace & Defence and Others), and Region - Partner & Customer Ecosystem (Product Services, Proposition & Key Features) Competitive Index & Regional Footprints by MarketDigits - Forecast 2024-2032

Industry : Chemicals & Materials | Pages : 190 Pages | Published On : Jul 2024

Market Overview

The industrial 3D printing market has experienced remarkable growth over the past decade, fueled by technological advancements and broader adoption across diverse industries. Once primarily used for prototyping, 3D printing has now become an essential tool for producing complex, customized components in sectors such as aerospace, automotive, healthcare, and manufacturing. This transition is driven by innovations in high-performance materials, enhancements in printing speed and accuracy, and the capability to fabricate intricate designs that were previously unattainable through conventional manufacturing techniques. In industries like aerospace and automotive, 3D printing is being utilized to reduce component weight, improve efficiency, and streamline supply chains through on-demand production. In healthcare, the technology is revolutionizing the creation of patient-specific implants, prosthetics, and even bio-printed tissues. Companies are increasingly dedicating resources to research and development to push the limits of industrial 3D printing, leading to a broader range of applications and further advancements in the field. The market is also being influenced by decreasing costs of 3D printing technologies, making them more accessible to small and medium-sized enterprises (SMEs). Additionally, the growing focus on sustainability in manufacturing is driving interest in 3D printing, which offers reduced material waste and more efficient resource utilization. However, the industry faces challenges such as the need for standardization, regulatory compliance, and the high initial investment required for industrial-grade printers. Despite these obstacles, the industrial 3D printing market is set for continued growth, with ongoing innovations likely to open up new opportunities across various industries.

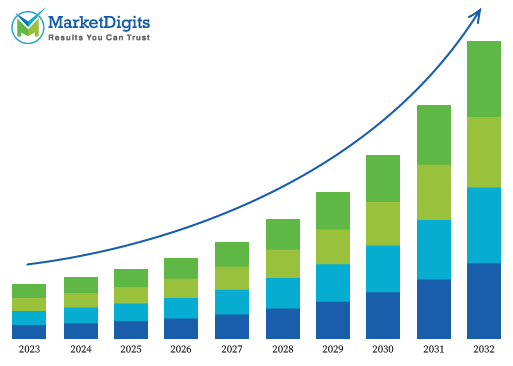

Industrial 3D Printing Market Size

| Report | Details |

|---|---|

| Market Size Value | USD 2.41 Billion in 2023 |

| Market Size Value | USD 7.96 Billion by 2032 |

| CAGR | 19.51 % |

| Forecast Period | 2024-2032 |

| Base Year | 2023 |

| Historic Data | 2020 |

Top key players are 3D Systems, Inc., 3DCeram, Arcam AB, Autodesk, Inc., Canon, Inc., Dassault Systemes, EnvisionTec, Inc., EOS (Electro Optical Systems) GmbH, ExOne, GE Additive, HP Inc., madeinspace.us, Materialise NV, Optomec, Inc., Organovo Holdings Inc., Proto Labs, Inc., Shapeways, Inc., Stratasys Ltd., Tiertime, Voxeljet AG and others. Market players are focusing on product advancements, such as user-friendly designs.

Increasing use 3D printing in aerospace and defense:

The increasing use of 3D printing in the aerospace and defense sectors is a significant driver of growth in the industrial 3D printing market. In these industries, the ability to produce complex, lightweight, and highly customized components is crucial. 3D printing, or additive manufacturing, offers unique advantages in this regard, allowing for the creation of intricate geometries that are difficult or impossible to achieve with traditional manufacturing methods. This capability is particularly valuable for producing parts that must meet stringent performance and safety standards, such as those used in aircraft engines, airframes, and defense systems. One of the key benefits of 3D printing in aerospace and defense is the reduction in weight of components, which directly contributes to fuel efficiency and operational performance. Lighter parts can lead to significant cost savings over the lifespan of an aircraft or defense vehicle, as they reduce fuel consumption and improve overall efficiency. Additionally, 3D printing enables the consolidation of multiple parts into a single component, further reducing weight, simplifying assembly processes, and enhancing the reliability of the final product. These advantages are driving the adoption of 3D printing technologies across the aerospace and defense sectors. Moreover, 3D printing offers the ability to produce parts on-demand and closer to the point of use, which is particularly beneficial in defense applications where rapid deployment and maintenance in remote or challenging environments are critical. This flexibility in manufacturing allows for quicker turnaround times, reduces the need for large inventories, and enhances supply chain resilience. As a result, the aerospace and defense industries are increasingly investing in 3D printing capabilities, recognizing the technology's potential to improve performance, reduce costs, and support mission-critical operations. This growing adoption is a key factor driving the overall expansion of the industrial 3D printing market.

Market Dynamics

Drivers:

- Increasing use 3D printing in aerospace and defense

- Increased focus on high-volume production in manufacturing

- Rising development in improved printing speed

Opportunities:

- Smart manufacturing with industry 4.0

- Growing use of technology in producing prototype equipment

- Substantial investments of governments and tech giant

Growing use of technology in producing prototype equipment:

The growing use of 3D printing technology in producing prototype equipment presents a significant opportunity in the industrial 3D printing market. Prototyping is a critical phase in the product development cycle, where designs are tested, iterated, and refined before full-scale production begins. Traditionally, prototyping has been a time-consuming and expensive process, often requiring specialized tooling and multiple iterations. However, 3D printing has revolutionized this process by enabling rapid, cost-effective production of prototypes with complex geometries and precise details, significantly reducing both development time and costs. One of the key advantages of using 3D printing for prototyping is the ability to quickly produce physical models directly from digital designs. This allows designers and engineers to test and validate their ideas in real-time, making adjustments and improvements on the fly. The speed and flexibility of 3D printing mean that multiple design iterations can be produced and evaluated within a short timeframe, leading to faster product development cycles. This capability is particularly valuable in industries such as automotive, aerospace, consumer electronics, and medical devices, where innovation and time-to-market are critical competitive factors. Moreover, 3D printing enables the creation of highly customized and intricate prototypes that closely resemble the final product in both form and function. This allows for more accurate testing of performance, fit, and usability before committing to expensive tooling and mass production. The ability to produce prototypes that mimic the final product's material properties and mechanical performance is a major advantage for industries that require high levels of precision and reliability. As more companies recognize the benefits of 3D printing in prototyping, the demand for industrial 3D printing solutions is expected to grow, creating significant opportunities for market expansion and innovation.

North America dominates the market for industrial 3D printing market:

North America leads the industrial 3D printing market, driven by its advanced manufacturing capabilities, high levels of technological innovation, and substantial investments in research and development. The region, particularly the United States, is home to many of the key players in industries like aerospace, automotive, and healthcare, which are at the forefront of adopting 3D printing technologies. The strong presence of research institutions, universities, and tech companies, along with supportive government policies and regulations, has helped solidify North America's dominance in this market. On the other hand, Asia-Pacific is rapidly emerging as a significant growth market for industrial 3D printing, fueled by increasing industrialization, a robust manufacturing base, and rising investments in new technologies. Countries like China, Japan, and South Korea are at the forefront of this growth, with China making notable strides in integrating 3D printing into its manufacturing processes to enhance efficiency and reduce dependency on traditional methods. The region's vast and diverse consumer market, coupled with government initiatives to support advanced manufacturing technologies, positions Asia-Pacific as a key area of expansion for industrial 3D printing in the coming years. The dynamics between North America and Asia-Pacific illustrate the global expansion of the industrial 3D printing market. While North America maintains its leadership due to its established infrastructure and innovation-driven economy, Asia-Pacific's rapid growth indicates a shifting market landscape. As more industries and companies in the region adopt 3D printing technologies, the global market is expected to see increased competition, accelerated innovation, and the development of new applications, benefiting the industry on a worldwide scale.

Printers is leading segment holds the largest market share:

in the industrial 3d printing market, the printers segment typically leads in terms of revenue and market share, driven by the high cost of industrial-grade 3d printers and the continuous advancements in printing technology. industrial 3d printers are essential for a wide range of applications, from producing complex prototypes to manufacturing end-use parts in industries like aerospace, automotive, and healthcare. the demand for high-performance, precise, and reliable 3d printing equipment has fueled the growth of this segment, making it the most significant contributor to the overall market. the printer’s segment's dominance is also supported by the increasing adoption of additive manufacturing across various industries. as more companies recognize the benefits of 3d printing, such as reduced lead times, cost savings in small-batch production, and the ability to create complex geometries, the demand for advanced 3d printing systems continues to rise. this has led to significant investments in research and development, resulting in innovations that further enhance printer capabilities, including faster printing speeds, higher resolution, and the ability to work with a broader range of materials. while the printers segment leads the market, it is closely followed by the materials and software segments, which are also experiencing strong growth. however, the capital-intensive nature of industrial 3d printers, combined with the ongoing need for upgrades and maintenance, ensures that the printers segment remains at the forefront of the industrial 3d printing market. this trend is expected to continue as industries increasingly integrate 3d printing into their production processes, further solidifying the importance of advanced 3d printing systems.

Segmentations analysis of industrial 3D printing market: -

- By Type:

- Printers

- Materials

- Software

- Services

- By Application:

- Prototyping

- Manufacturing

- High Voltage

- By End-User:

- Automotive

- Electrical & Electronics

- Healthcare

- Aerospace & Defense

- Others

- By Region:

- North America

- U.S.

- Canada

- Latin America

- Brazil

- Mexico

- Argentina

- Colombia

- Chile

- Peru

- Rest of Latin America

- Europe

- Germany

- France

- Italy

- Spain

- U.K.

- BENELUX

- CIS & Russia

- Nordics

- Austria

- Poland

- Rest of Europe

- Asia Pacific

- North America

- China

- Japan

- South Korea

- India

- Thailand

- Indonesia

- Malaysia

- Vietnam

- Australia & New Zealand

- Rest of Asia Pacific

- Middle East & Africa

- Saudi Arabia

- UAE

- South Africa

- Nigeria

- Egypt

- Israel

- Turkey

- Rest of MEA

Recent Developments:

- In March 2023, 3D Systems, Inc. announced the launch of NextDent Cast and NextDent Base, two new printing materials, and NextDent LCD1, a printing platform. The materials are designed to enhance material properties, and the printing platform is an easy-to-use small-format printer. With these launches, the company aimed to aid its customers in accelerating additive manufacturing adoption.

- In November 2023, Autodesk Inc. announced the launch of Autodesk AI. This new technology is available in Autodesk products and is designed to provide customers with generative capabilities and intelligent assistance. With the launch of this new technology in Autodesk products, the company aimed to minimize errors by automating repetitive tasks and the needs of its customers.

- In February 2022, Dassault Systèmes has announced a strategic partnership with Cadence Design Systems, Inc. to provide integrated solutions for the development of high-performance electronic systems to enterprise customers in a variety of vertical markets, such as high tech, industrial equipment, and transportation and mobility, aerospace and defense, and healthcare.

Answers to Following Key Questions:

- What will be the industrial 3D printing market’s trends & growth rate? What analysis has been done of the prices, sales, and volume of the top producers in the industrial 3D printing market?

- What are the main forces behind worldwide industrial 3D printing market? Which companies dominate industrial 3D printing market?

- Which companies dominate industrial 3D printing market? Which business possibilities, dangers, and tactics did they embrace in the market?

- What are the global insight engines industry's suppliers' opportunities and dangers in industrial 3D printing market?

- What is the insight engines industry's regional sales, income, and pricing analysis? In the industrial 3D printing market, who are the distributors, traders, and resellers?

- What are the main geographic areas for various trades that are anticipated to have astounding expansion over the industrial 3D printing market?

- What are the main geographical areas for various industries that are anticipated to observe astounding expansion for industrial 3D printing market?

- What are the dominant revenue-generating regions for industrial 3D printing market, as well as regional growth trends?

- By the end of the forecast period, what will the market size and growth rate be?

- What are the main industrial 3D printing market trends that are influencing the market's expansion?

- Which key product categories dominate industrial 3D printing market? What is industrial 3D printing market market’s main applications?

- In the coming years, which industrial 3D printing market technology will dominate the market?

TOC

Table and Figures

Methodology:

At MarketDigits, we take immense pride in our 360° Research Methodology, which serves as the cornerstone of our research process. It represents a rigorous and comprehensive approach that goes beyond traditional methods to provide a holistic understanding of industry dynamics.

This methodology is built upon the integration of all seven research methodologies developed by MarketDigits, a renowned global research and consulting firm. By leveraging the collective strength of these methodologies, we are able to deliver a 360° view of the challenges, trends, and issues impacting your industry.

The first step of our 360° Research Methodology™ involves conducting extensive primary research, which involves gathering first-hand information through interviews, surveys, and interactions with industry experts, key stakeholders, and market participants. This approach enables us to gather valuable insights and perspectives directly from the source.

Secondary research is another crucial component of our methodology. It involves a deep dive into various data sources, including industry reports, market databases, scholarly articles, and regulatory documents. This helps us gather a wide range of information, validate findings, and provide a comprehensive understanding of the industry landscape.

Furthermore, our methodology incorporates technology-based research techniques, such as data mining, text analytics, and predictive modelling, to uncover hidden patterns, correlations, and trends within the data. This data-driven approach enhances the accuracy and reliability of our analysis, enabling us to make informed and actionable recommendations.

In addition, our analysts bring their industry expertise and domain knowledge to bear on the research process. Their deep understanding of market dynamics, emerging trends, and future prospects allows for insightful interpretation of the data and identification of strategic opportunities.

To ensure the highest level of quality and reliability, our research process undergoes rigorous validation and verification. This includes cross-referencing and triangulation of data from multiple sources, as well as peer reviews and expert consultations.

The result of our 360° Research Methodology is a comprehensive and robust research report that empowers you to make well-informed business decisions. It provides a panoramic view of the industry landscape, helping you navigate challenges, seize opportunities, and stay ahead of the competition.

In summary, our 360° Research Methodology is designed to provide you with a deep understanding of your industry by integrating various research techniques, industry expertise, and data-driven analysis. It ensures that every business decision you make is based on a well-triangulated and comprehensive research experience.

• Product Planning Strategy

• New Product Stratergy

• Expanded Research Scope

• Comprehensive Research

• Strategic Consulting

• Provocative and pragmatic

• Accelerate Revenue & Growth

• Evaluate the competitive landscape

• Optimize your partner network

• Analyzing industries

• Mapping trends

• Strategizing growth

• Implementing plans

Covered Key Topics

Growth Opportunities

Market Growth Drivers

Leading Market Players

Company Market Share

Market Size and Growth Rate

Market Trend and Technological

Research Assistance

We will be happy to help you find what you need. Please call us or write to us:

+1 510-730-3200 (USA Number)

Email: sales@marketdigits.com